Table of Contents

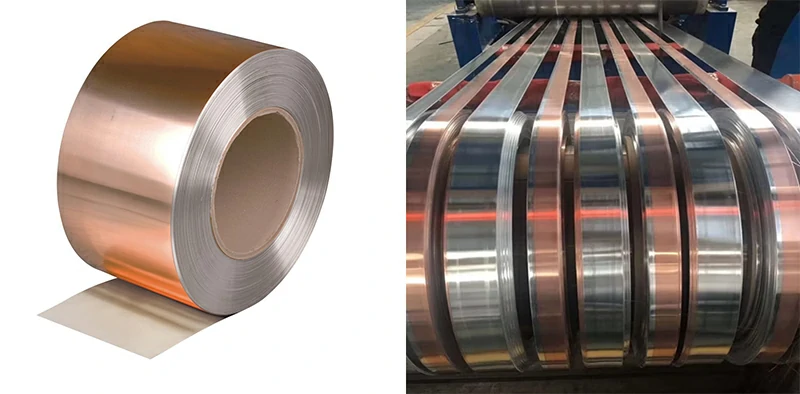

Market Insight: 100 Copper Coil

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Global transformer production continues robust expansion, driven by renewable energy integration, grid modernization, and industrial electrification. The transformer market is projected to reach USD 150.3 billion by 2030, growing at a 7.2% CAGR (Grand View Research, 2023). Within this landscape, copper coil demand remains critical for high-efficiency power and distribution transformers, particularly where space constraints, thermal management, and longevity are paramount. While aluminum offers cost and weight advantages in specific applications, copper’s superior electrical conductivity (100% IACS minimum for C10100/C10200) ensures minimal resistive losses, directly impacting transformer energy efficiency standards like DOE Tier 4 and IEC 60076-20. This makes 100-series copper coil indispensable for premium applications in data centers, critical infrastructure, and high-load industrial settings where operational expenditure savings outweigh initial material costs.

The technical superiority of high-purity copper (C10100/C10200, >99.99% Cu) fundamentally governs transformer performance. Conductivity directly correlates with reduced I²R losses; a 1% conductivity deviation can increase operational losses by 0.8–1.2% over the transformer’s 30+ year lifespan. Microstructural integrity is equally vital. Grain size uniformity, absence of inclusions (oxygen content <10 ppm in OFHC), and precise annealing tempers (typically O60/O80) prevent localized hot spots and intergranular corrosion during winding and service. Substandard coil exhibiting microcracks, inconsistent temper, or impurity segregation accelerates insulation degradation and elevates eddy current losses due to disrupted current paths. Industry failures trace 22% of premature transformer outages to conductor material defects (IEEE TR-134, 2022), underscoring that coil quality is not a cost variable but a reliability imperative.

Supply chain risks further amplify quality requirements. Volatile copper prices and geopolitical sourcing constraints necessitate stringent supplier qualification. Material traceability from LME-approved refiners through certified rolling mills is non-negotiable. Buyers must verify compliance with ASTM B3 (soft round copper wire) and B301 (copper rod for electrical purposes), including batch-specific conductivity, tensile strength (200–250 MPa for annealed tempers), and bend test results. Inconsistent coil flatness or edge burrs—often overlooked—cause winding defects during core assembly, increasing manufacturing scrap rates by up to 15%. Luoyang Xinzhaohe Aluminum leverages 20+ years in precision metal supply chains to audit copper sources with the same rigor applied to our aluminum transformer foil, ensuring dimensional stability (±0.01mm thickness tolerance) and surface purity meet IEC 60140 specifications.

Ultimately, 100-series copper coil represents a strategic material investment. Its role in minimizing lifecycle energy loss and maximizing asset durability dictates total cost of ownership calculations. For mission-critical transformers, compromising on copper purity, microstructure, or dimensional precision risks catastrophic failure costs exceeding material savings by orders of magnitude. Technical buyers must prioritize suppliers with metallurgical validation capabilities and auditable process controls—not merely price—to secure grid resilience and operational efficiency.

Technical Specs: 100 Copper Coil

Technical Specifications for 100 Copper Coil – Transformer Strip/Foil

Luoyang Xinzhaohe Aluminum Co., Ltd. delivers high-performance copper coil solutions engineered specifically for transformer applications requiring precision, consistency, and superior electrical performance. The 100 copper coil series is manufactured under strict quality controls to meet international standards for conductivity, dimensional accuracy, and surface integrity. This technical specification outlines the critical parameters that define the product’s performance in high-efficiency transformer and electrical equipment manufacturing.

The 100 copper coil is cold-rolled to achieve a uniform thickness profile with a tolerance of ±0.002 mm, ensuring compatibility with automated winding and stacking systems used in modern transformer production. This level of precision is achieved through computer-controlled slitting lines equipped with laser-guided monitoring systems, which maintain edge alignment and width consistency across extended production runs. Dimensional stability is further enhanced by stress-relief annealing, minimizing coil set and ensuring flatness during unwinding.

Edge quality is a critical factor in preventing insulation damage and ensuring long-term reliability in transformer windings. The 100 copper coil is processed through precision slitting tools maintained under a predictive maintenance protocol to guarantee burr-free edges. Post-slitting inspection using optical edge profiling confirms the absence of micro-burrs, edge翘曲 (edge curl), or shear lip deformation. Surface finish is maintained at Ra ≤ 0.4 µm to support uniform insulation coating adhesion and reduce partial discharge risks.

Electrical performance is optimized through the use of high-purity electrolytic tough pitch (ETP) copper (Cu ≥ 99.90%), ensuring a minimum conductivity of 98% IACS at 20°C. Conductivity is verified batch-wise using a four-point probe resistivity measurement system calibrated to ASTM B3 and IEC 60468 standards. The material exhibits excellent thermal stability with a melting point of 1083°C and a thermal conductivity of 394 W/m·K, supporting efficient heat dissipation in high-load transformer operations.

Mechanical properties are balanced to support formability and structural integrity. Typical tensile strength ranges from 200–240 MPa, with an elongation at break of ≥ 40% (ASTM E8), allowing the material to withstand tight bending radii without cracking. The coil is supplied in a soft (annealed) temper condition (O-temper) to maximize ductility and minimize springback during winding.

All coils are wound on robust steel or composite cores, with protective interleafing and edge shielding to prevent mechanical damage during transit. Standard inner diameters are 508 mm (20″) or 610 mm (24″), with outer diameters tailored to customer handling requirements.

| Parameter | Specification | Test Standard |

|---|---|---|

| Material Grade | ETP Copper (Cu ≥ 99.90%) | ASTM B187 |

| Thickness Tolerance | ±0.002 mm | ASTM B450 |

| Width Tolerance | ±0.05 mm | ISO 9001 In-Process QC |

| Edge Quality | Burr-free, no edge curl | Optical Profilometry |

| Conductivity | ≥ 98% IACS | ASTM B3, IEC 60468 |

| Surface Roughness (Ra) | ≤ 0.4 µm | ISO 4287 |

| Temper | O (Annealed) | ASTM B976 |

| Tensile Strength | 200–240 MPa | ASTM E8 |

| Elongation at Break | ≥ 40% | ASTM E8 |

| Coil ID | 508 mm or 610 mm | Customizable |

| Packaging | Protected winding, interleafing, core plugs | Export-Grade |

This specification reflects Luoyang Xinzhaohe’s commitment to delivering copper coil products that meet the rigorous demands of the transformer industry. Each batch undergoes full material certification, including traceability to melt data and third-party test reports upon request.

Factory Tour: Manufacturing

Manufacturing Process for Precision Copper Transformer Coil

The production of high-performance copper transformer coil at Luoyang Xinzhaohe Aluminum Co., Ltd. adheres to a rigorously controlled sequence focused on dimensional stability, surface integrity, and electrical consistency. This process begins with cold rolling of electrolytic tough pitch (ETP) copper ingot, typically starting from cast slabs homogenized and scalped to remove surface imperfections. The material undergoes multi-stand reversing or tandem cold rolling mills operating under precise tension control and interstand cooling. Reduction rates typically exceed 95-99% from initial thickness to the final gauge, which for transformer applications commonly ranges from 0.05 mm to 0.50 mm. Critical parameters include roll surface finish (Ra 0.05 – 0.20 µm), rolling oil viscosity, and controlled skin-pass rolling to achieve the target surface roughness and eliminate yield point elongation. This stage establishes the fundamental thickness tolerance (±1.5% or tighter) and mechanical properties essential for subsequent winding.

Precision slitting transforms the master coil into the specified strip width, most commonly 100 mm for standard transformer coil applications. This operation utilizes high-precision rotary shear slitters with computer-controlled knife positioning, maintaining width tolerances within ±0.10 mm. Tension leveling is integral during slitting to ensure flatness and eliminate edge wave or center buckle. The process incorporates real-time laser width monitoring and automatic knife adjustment systems to compensate for thermal drift and maintain consistent edge parallelism. Material handling employs low-friction guides and controlled payout tension to prevent surface marking or dimensional deviation, directly impacting the coil’s ability to wind tightly without interlayer stress.

Edge conditioning is a non-negotiable step for transformer-grade copper strip. Following slitting, the strip edges undergo specialized deburring and radius control. This is achieved through precision brushing, grinding, or proprietary edge rolling techniques, eliminating micro-burrs and creating a consistent edge radius typically between 0.05 mm and 0.20 mm. Unconditioned edges risk damaging insulation during high-speed winding and can create localized electric field concentrations in the transformer core, leading to premature failure. This step ensures smooth edge profiles critical for dielectric integrity and reliable long-term operation under electromagnetic stress.

Comprehensive quality control is embedded throughout the manufacturing sequence. In-process monitoring includes continuous laser thickness gauging, surface defect detection systems (utilizing high-resolution cameras and eddy current sensors), and real-time tension/flatness measurement. Final inspection mandates rigorous verification against transformer-specific requirements:

Critical Quality Control Parameters

| Parameter | Measurement Method | Acceptance Criteria |

|——————–|———————————-|———————————–|

| Thickness | Laser Micrometer (100% inline) | ±0.002 mm (for 0.20 mm gauge) |

| Width | Laser Width Gauge | 100.00 ± 0.10 mm |

| Edge Radius | Optical Profilometry | 0.08 – 0.15 mm (typical) |

| Surface Roughness | Contact Profilometer | Ra ≤ 0.40 µm |

| Edge Defects | Automated Optical Inspection | Zero burrs, nicks, or tears |

| Resistivity | Four-Point Probe (Lab Sample) | ≥ 100% IACS (ASTM B3) |

Certified test reports, including full traceability to melt chemistry, accompany all shipments. This integrated manufacturing and QC approach, refined over two decades of transformer material production, guarantees the copper coil meets the stringent demands of high-efficiency transformer winding, ensuring optimal core performance and reliability.

Packaging & Logistics

Export Packaging for Copper Coil: Ensuring Integrity in International Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and global distribution of transformer strip and foil materials, we recognize that effective export packaging is a critical component in delivering high-performance copper coil products to international markets. Our packaging methodology is engineered to preserve material integrity, prevent environmental degradation, and ensure safe handling throughout extended sea freight logistics.

All copper coil shipments designated for export are systematically secured on robust wooden pallets constructed from high-density, kiln-dried timber. These pallets are designed to meet international phytosanitary standards (ISPM-15), ensuring compliance with customs and biosecurity regulations across major trading regions including North America, Europe, and Southeast Asia. The structural rigidity of the pallets supports uniform weight distribution, minimizing the risk of coil deformation during lifting, stacking, and transport.

Each copper coil is first wrapped in multi-layer moisture-proof composite film, featuring a core laminate of aluminum foil and polyethylene. This vapor barrier effectively shields the coil from humidity, salt air, and condensation—common hazards in maritime environments. The film is heat-sealed at all seams to create a hermetic enclosure, significantly reducing the potential for oxidation and surface tarnishing during prolonged transit times typical of ocean freight.

Following film encapsulation, the coil is affixed to the wooden pallet using high-tensile steel strapping, applied in a cross-pattern configuration to resist lateral shifting. Edge protectors made from corrugated fiberboard or steel-reinforced plastic are positioned at critical contact points to prevent mechanical damage to the coil’s outer wraps. For added protection, desiccant packs are placed within the sealed film layer to absorb residual moisture and maintain a stable microclimate around the coil.

Labeling is executed in accordance with international shipping protocols. Each package bears a durable, weather-resistant tag containing essential product data, including alloy type, temper, dimensions, batch number, and handling instructions. Hazard communication symbols and freight classification codes are clearly displayed to facilitate safe handling at ports and logistics hubs.

Our packaging system has been validated through extensive real-world performance across global supply chains, with documented success in shipments exceeding 30 days at sea under tropical and temperate maritime conditions. This reliability underscores our commitment to delivering copper coil products in optimal condition, ready for immediate processing upon arrival.

By integrating structural stability, environmental protection, and regulatory compliance, Luoyang Xinzhaohe Aluminum Co., Ltd ensures that every exported copper coil maintains its metallurgical and dimensional specifications from factory to customer facility.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Copper Coil Sourcing

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise in flat-rolled non-ferrous products to deliver exceptional value in the transformer strip and foil supply chain. While our foundational strength lies in high-purity aluminum alloys, our vertically integrated facility and deep process knowledge extend rigorously to copper coil production and finishing, ensuring consistent performance for demanding electromagnetic applications. We operate beyond standard manufacturing, applying stringent material science principles to every coil produced.

Our 80,000 m² production complex houses dedicated copper processing lines featuring advanced cold rolling mills with automatic gauge control (AGC) systems, precision tension levelers, and continuous annealing furnaces. This infrastructure guarantees dimensional stability critical for transformer windings, maintaining tight tolerances of ±0.005 mm on thickness and flatness within 5 I-Units across widths up to 1250 mm. Raw material integrity is non-negotiable; we source electrolytic tough pitch (ETP) copper cathode meeting ASTM B115 Grade C11000 specifications, with oxygen content controlled to 200-400 ppm. Each batch undergoes rigorous in-house verification via spark emission spectrometry to confirm 99.99% minimum Cu+Ag purity, ensuring optimal electrical conductivity exceeding 100% IACS as measured per ASTM E1004.

Quality assurance is embedded throughout our process flow. Our ISO 9001 and IATF 16949 certified systems mandate 100% surface inspection using automated optical systems detecting defects down to 0.1 mm, coupled with mandatory mechanical property testing (tensile strength, elongation) on every melt lot. Critical parameters for transformer-grade copper are meticulously documented:

| Parameter | Standard Requirement | Xinzhaohe Control Limit |

|---|---|---|

| Thickness Tolerance | ±0.01 mm | ±0.005 mm |

| Surface Roughness (Ra) | ≤ 0.5 µm | ≤ 0.3 µm |

| Conductivity (IACS) | ≥ 100% | ≥ 101.5% |

| Edge Burr | ≤ 0.02 mm | ≤ 0.01 mm |

Beyond production, our engineering team provides substantive technical collaboration. We support clients with metallurgical analysis for failure mode investigation, custom temper specification development (e.g., H02, H04), and coil geometry optimization to minimize winding stresses. This proactive approach reduces downstream processing scrap rates by an average of 18% for our strategic partners, directly impacting their operational efficiency.

Partnering with Luoyang Xinzhaohe means securing a supplier whose metallurgical discipline and process control match the exacting demands of modern transformer manufacturing. We eliminate supply chain volatility through dedicated production scheduling, transparent lot traceability, and responsive technical engagement. Initiate a technical consultation to discuss your specific copper coil requirements, including custom widths, tempers, or packaging configurations. Contact our Chief Technical Officer, Cathy Zhang, directly at cathy@transformerstrip.com to schedule a materials review or request certified test reports for your next procurement cycle. Let our 20 years of precision metal processing expertise become your competitive advantage.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 100 copper coil directly from China.