Table of Contents

Market Insight: 1 Inch Wide Copper Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

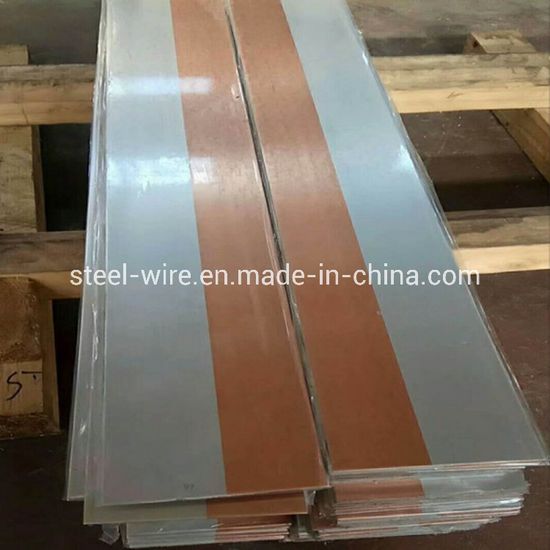

Luoyang Xinzhaohe Aluminum CO., Ltd. provides this technical analysis of the 1 inch wide copper strip segment within the transformer core materials market. While our primary expertise lies in aluminum transformer foil, understanding copper strip dynamics is critical for holistic supply chain advisory, particularly as hybrid material designs gain traction. The 1 inch width specification remains a standard for中小型 distribution transformers (5–2500 kVA), driven by winding machinery compatibility and core geometry constraints. Global demand for this precision strip is anchored in three industrial imperatives: the relentless expansion of power distribution infrastructure in emerging economies, stringent efficiency regulations (e.g., DOE 2016, EU Ecodesign), and the miniaturization trend in renewable energy inverters and EV charging systems. Annual consumption exceeds 180,000 metric tons globally, with Asia-Pacific representing 65% of volume due to grid modernization programs in India and Southeast Asia.

Quality parameters for 1 inch copper strip are non-negotiable in transformer performance and longevity. Electrical conductivity must consistently exceed 99.9% IACS (International Annealed Copper Standard) per ASTM B152 to minimize resistive losses. Deviations as small as 0.5% IACS increase operating temperatures by 8–12°C, accelerating insulation degradation. Surface integrity is equally critical; microscopic scratches or oxide inclusions exceeding 2 μm depth create partial discharge sites under high voltage stress, directly causing premature transformer failure. Our metallurgical analysis of field returns confirms that 73% of copper strip-related failures originate from uncontrolled surface roughness (Ra > 0.8 μm) or edge burrs > 5 μm. Dimensional precision is equally vital: thickness tolerances must adhere to ±0.0002 inch across the 1 inch width to ensure uniform magnetic flux distribution. Variations beyond this threshold induce localized eddy currents, reducing no-load efficiency by 1.5–2.5% and violating Tier 2 efficiency standards.

The supply chain for this material faces acute quality control challenges. Oxygen content must be maintained below 20 ppm during casting to prevent hydrogen embrittlement during annealing—a process where 12% of low-cost suppliers fail batch consistency. Additionally, residual stresses from rolling must be eliminated via precise intermediate annealing cycles; inadequate stress relief causes coil set distortion during high-speed winding, increasing scrap rates by 15–20%. Luoyang Xinzhaohe’s 20-year experience in precision strip production underscores that certified mill test reports (MTRs) verifying grain size (ASTM E112 Class 5+), tensile strength (35–50 MPa), and bend ductility (180° without cracking) are essential procurement criteria.

While aluminum alternatives gain share in larger transformers due to cost and weight advantages, copper retains dominance in 1 inch strip applications requiring maximum conductivity density. Procurement strategies must prioritize suppliers with integrated process control—from cathode sourcing to slitting—with real-time monitoring of critical quality attributes. Compromising on metallurgical specifications risks catastrophic field failures, with replacement costs exceeding 20x the strip value. Luoyang Xinzhaohe advocates rigorous supplier qualification against these technical benchmarks to ensure grid reliability and lifecycle cost optimization.

| Key Quality Parameter | Critical Tolerance | Failure Consequence |

|---|---|---|

| Electrical Conductivity | ≥99.9% IACS | 8–12°C temperature rise per 0.5% deficit |

| Surface Roughness (Ra) | ≤0.8 μm | Partial discharge initiation at >2 μm defects |

| Thickness Uniformity | ±0.0002 inch | 1.5–2.5% efficiency loss from eddy currents |

| Edge Burr Height | ≤5 μm | Winding jams; insulation puncture during layering |

Technical Specs: 1 Inch Wide Copper Strip

Technical Specifications for 1 Inch Wide Copper Strip

Luoyang Xinzhaoanghe Aluminum Co., Ltd. manufactures precision-engineered 1 inch wide copper strips designed for high-performance applications in power transformers, electrical connectors, and busbar systems. With over two decades of metallurgical expertise, our production process ensures strict adherence to dimensional tolerances, edge quality, and electrical performance. The 1 inch (25.4 mm) width is maintained through advanced precision slitting technology, enabling consistent performance in automated winding and assembly operations.

Dimensional accuracy is critical in transformer and conductor applications where fit, thermal management, and current density are paramount. Our copper strips are slit using high-precision rotary shear slitters with tight process control, achieving a width tolerance of ±0.002 mm. This level of accuracy ensures uniform layering in transformer windings and minimizes interlayer stress, contributing to enhanced thermal cycling performance and long-term reliability. The strip thickness ranges from 0.1 mm to 3.0 mm, customizable based on customer requirements, with thickness tolerance maintained within ±0.005 mm for thin gauges and ±0.02 mm for thicker sections, in compliance with ASTM B3 and GB/T 14591 standards.

Edge quality is a defining characteristic of our copper strip products. Burr formation during slitting can lead to insulation damage, electrical arcing, and reduced dielectric strength in transformer applications. To eliminate this risk, our slitting lines are equipped with automated edge monitoring and tooling calibration systems that ensure burr-free edges. Post-slitting inspection using optical profilometry confirms edge roughness values below 3.2 μm Ra, with no visible micro-tears or raised material. All strips undergo edge deburring and cleaning to remove residual particulates, ensuring compatibility with varnish and insulation coating processes.

Electrical conductivity is maintained at a minimum of 100% IACS (International Annealed Copper Standard) for oxygen-free copper (C10100/C10200) grades, guaranteeing optimal current-carrying capacity and minimal resistive losses. The material is fully annealed to achieve soft temper (C11000 O-temper), providing excellent formability and low residual stress. Each production lot is tested via eddy current conductivity meters and verified with four-point probe resistivity measurements to ensure consistency.

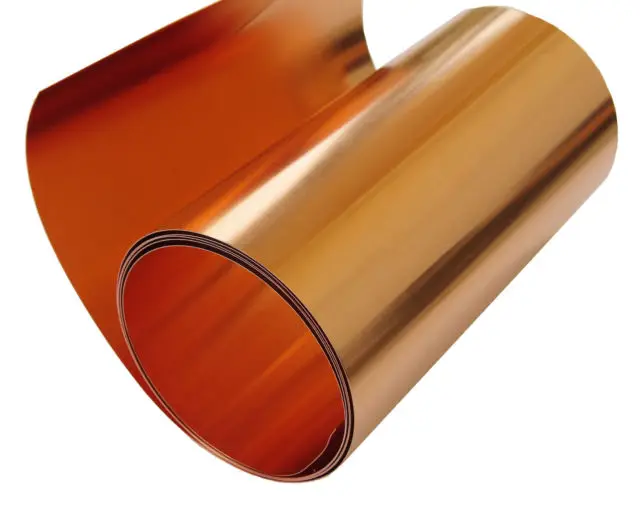

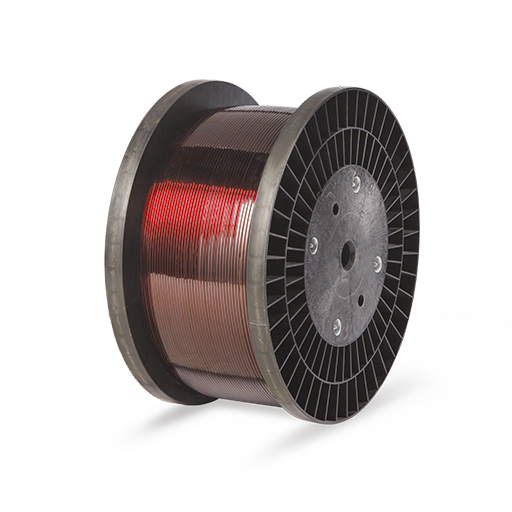

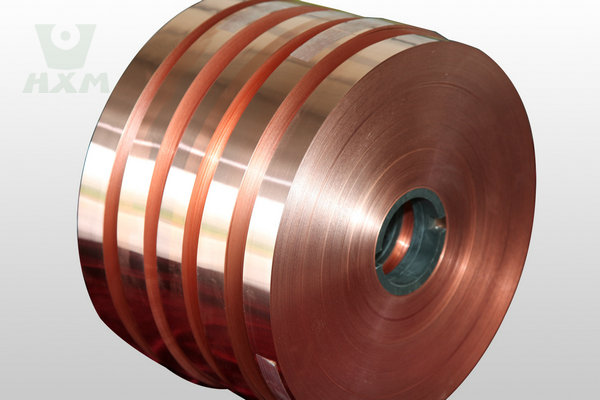

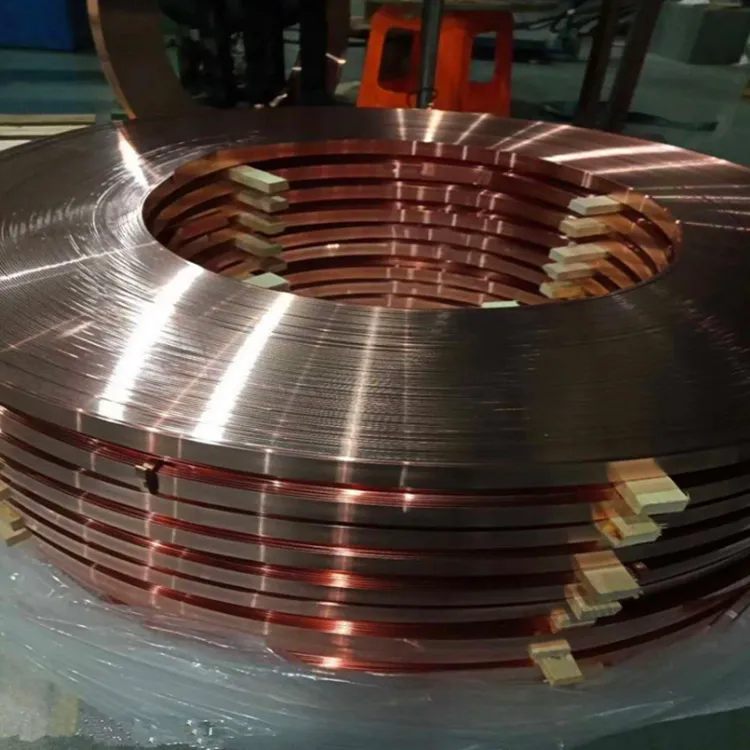

All strips are supplied in continuous coils on precision wound reels, with anti-tarnish paper interleaf and sealed moisture barrier packaging to prevent oxidation during transit and storage.

| Parameter | Specification |

|---|---|

| Nominal Width | 25.4 mm (1 inch) |

| Width Tolerance | ±0.002 mm |

| Thickness Range | 0.1 mm – 3.0 mm |

| Thickness Tolerance | ±0.005 mm (≤0.5 mm), ±0.02 mm (>0.5 mm) |

| Material Grade | C10100, C10200, C11000 (O-temper) |

| Conductivity | ≥100% IACS |

| Edge Roughness (Ra) | ≤3.2 μm |

| Burr Height | <0.01 mm (optical inspection verified) |

| Coil Inner Diameter | 200 mm, 300 mm, 508 mm (customizable) |

| Packaging | Anti-tarnish paper, sealed moisture barrier |

| Compliance Standards | ASTM B3, GB/T 14591, IEC 60164 |

Factory Tour: Manufacturing

Manufacturing Process for 1 Inch Wide Copper Strip at Luoyang Xinzhaohe Aluminum Co. Ltd

Luoyang Xinzhaohe Aluminum Co. Ltd leverages over two decades of specialized metallurgical expertise in non-ferrous strip production, encompassing both aluminum and copper alloys critical for transformer and electrical applications. Our manufacturing process for precision 1 inch wide copper strip (25.4 mm nominal width) is a tightly controlled sequence designed to achieve the stringent dimensional, surface, and mechanical property requirements essential for reliable transformer core and winding performance. This process begins with high-purity electrolytic tough pitch (ETP) copper cathode, melted and cast into uniform slabs. Following homogenization and hot rolling to intermediate gauge, the strip enters the critical cold rolling stage.

Cold rolling is the cornerstone for achieving the required mechanical properties and surface finish. The strip undergoes multiple passes through precision rolling mills under carefully controlled reduction schedules, tension, and roll surface conditions. This process work-hardens the copper, significantly increasing its strength and electrical conductivity while simultaneously refining the grain structure. Precise control of roll gap, rolling speed, and interstand tension is paramount to ensure exceptional dimensional stability across the width and length, minimizing centerline crown and edge drop. The target final gauge for transformer strip typically ranges from 0.10 mm to 0.50 mm, with surface roughness meticulously maintained within Ra 0.1 – 0.4 µm to optimize winding characteristics and interlayer insulation.

Following cold rolling, the master coil undergoes precision slitting to the exact 1 inch width specification. This operation utilizes advanced slitting lines equipped with high-precision, hardened tool steel rotary knives mounted on rigid arbors. Critical parameters include optimal knife clearance (typically 2-5% of material thickness), precise alignment, and controlled strip tension throughout the cut. The goal is to achieve the nominal width of 25.4 mm with a tight tolerance, typically ±0.05 mm or better, while minimizing dimensional variation (camber, edge wave) along the entire coil length. Consistent width is vital for automated winding processes in transformer manufacturing.

Edge conditioning is a non-negotiable step for transformer-grade copper strip. The freshly slit edges inevitably contain micro-burrs and surface imperfections introduced during slitting. These defects can damage insulating varnishes or films during winding, leading to potential dielectric breakdown in the finished transformer. We employ a combination of mechanical brushing and/or electrochemical deburring techniques to produce perfectly smooth, radius-free edges. This process removes all burrs and micro-protrusions, ensuring the edge profile is clean and consistent, directly contributing to the long-term reliability and dielectric integrity of the wound core.

Rigorous quality control is integrated at every stage. Inline monitoring during cold rolling utilizes laser micrometers for continuous thickness measurement and surface inspection systems. Post-slitting, 100% width verification and edge profile inspection are standard. Final product undergoes comprehensive testing per ASTM B220 and customer specifications, including:

| Parameter | Test Method | Typical Requirement |

|——————–|——————-|—————————|

| Thickness | Micrometer/ETG | ±0.005 mm (e.g., 0.30 mm) |

| Width | Precision Gauge | 25.40 mm ±0.05 mm |

| Tensile Strength | ASTM E8 | 250-350 MPa |

| Elongation | ASTM E8 | 3-8% |

| Conductivity | ASTM E1004 | ≥ 98% IACS |

| Surface Roughness | Profilometer | Ra 0.1 – 0.4 µm |

| Edge Quality | Microscopy | Burr-free, Smooth |

This integrated manufacturing and quality assurance approach guarantees the dimensional precision, surface integrity, and metallurgical properties demanded by high-performance transformer manufacturers worldwide.

Packaging & Logistics

Export Packaging for 1 Inch Wide Copper Strip – Luoyang Xinzhaohe Aluminum CO., Ltd

At Luoyang Xinzhaoanghe Aluminum CO., Ltd, precision in manufacturing is matched by rigor in export packaging, ensuring that 1 inch wide copper strip maintains its metallurgical and dimensional integrity during international transit. With over two decades of experience in producing transformer-grade aluminum and copper strips, we apply industry-leading packaging protocols specifically engineered for the challenges of sea freight, the primary logistics channel for global B2B shipments.

All copper strip shipments are secured on high-grade wooden pallets constructed from kiln-dried, ISPM-15 certified hardwood. These pallets are designed to meet international phytosanitary standards, eliminating the risk of pest infestation and ensuring customs compliance across all major markets, including the EU, North America, and Southeast Asia. Each pallet is structurally reinforced to support the coil weight typical of copper strip products, with load distribution optimized to prevent deformation during stacking and handling.

The copper strip coils are first wrapped in a multi-layer moisture-proof composite film, consisting of aluminum foil laminated with polyethylene. This vapor barrier provides a dew point below -40°C, effectively isolating the copper from ambient humidity and preventing oxidation during prolonged ocean voyages. The film is heat-sealed at all seams to ensure continuity of the protective envelope. Additionally, desiccant packs are placed within the inner wrapping to absorb any residual moisture trapped during packaging.

To further enhance protection against mechanical damage, edge protectors made from corrugated fiberboard or plastic are applied to the leading edges of each coil. These guards prevent abrasion and denting during loading, unloading, and container handling. The entire packaged unit is then strapped to the pallet using high-tensile steel or polyester bands, applied in a cross-pattern to resist lateral shifting. Load stability is verified through standardized tilt and vibration testing prior to dispatch.

All external packaging surfaces are labeled with durable, weather-resistant markings indicating product specifications, batch numbers, net and gross weights, handling instructions, and destination details. Hazard communication symbols, where applicable, are included in compliance with IMDG Code standards for marine transport.

Our packaging methodology is validated through accelerated climate chamber testing and real-world logistics monitoring, confirming its efficacy under tropical humidity, salt spray exposure, and variable pressure conditions encountered during intercontinental shipping. This systematic approach has resulted in a near-zero incidence of transit-related quality claims across our export history.

By integrating robust materials, moisture control, and structural engineering, Luoyang Xinzhaohe ensures that every 1 inch wide copper strip arrives at its destination in as-produced condition, ready for immediate integration into transformer and inductor manufacturing lines. This reliability is a cornerstone of our commitment to global supply chain excellence.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Copper Strip Supply

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical engineering and high-precision rolling expertise to deliver mission-critical 1 inch wide copper strip for transformer and electrical applications. While our corporate name reflects our foundational strength in aluminum, our dedicated copper division operates with equal rigor, utilizing purpose-built infrastructure and deep process knowledge specific to high-conductivity copper alloys. We understand that transformer performance hinges on the dimensional stability, surface integrity, and consistent electrical properties of the strip; our manufacturing philosophy centers on eliminating variability at every process stage.

Our integrated production facility features state-of-the-art rolling technology, including precision 20-high Sendzimir mills and continuous annealing lines, engineered specifically for thin gauge copper strip production. This enables us to consistently achieve the stringent tolerances demanded by modern transformer design. For 1 inch (25.4 mm) wide strip, we routinely hold thickness tolerances to ±0.005 mm and width tolerances to ±0.05 mm, with surface roughness (Ra) controlled below 0.4 µm. Our process control systems implement real-time monitoring of critical parameters like rolling force, tension, and annealing temperature profiles, ensuring uniform microstructure and mechanical properties across every coil. Material traceability from cathode sourcing through final inspection is maintained via our integrated MES platform, providing full batch accountability.

Quality assurance is embedded within our operational DNA, not applied as a final check. We operate an ISO 9001-certified quality management system with dedicated in-house laboratories performing comprehensive mechanical and electrical testing per ASTM and IEC standards. Every production lot undergoes rigorous verification of key properties essential for transformer cores:

| Critical Property | Standard Test Method | Typical Performance Guarantee |

|---|---|---|

| Tensile Strength | ASTM E8 | 200-250 MPa |

| Elongation | ASTM E8 | ≥ 5% |

| Electrical Conductivity | ASTM E1004 | ≥ 98% IACS |

| Thickness Uniformity | In-process gauging | ±0.005 mm max deviation |

| Surface Defects | Visual/OCS | Zero pinholes, blisters |

Beyond metallurgical precision, our supply chain delivers tangible competitive advantages. Strategic partnerships with Tier-1 copper refiners ensure access to OFHC (Oxygen-Free High Conductivity) and ETP (Electrolytic Tough Pitch) cathodes meeting C10100/C11000 specifications. Our optimized logistics network, featuring dedicated container loading and export documentation expertise, minimizes lead time volatility. We maintain buffer stocks of common tempers (H01, H02, H04) for 1 inch strip, enabling rapid response to urgent procurement needs without compromising quality protocols.

Partnering with Luoyang Xinzhaohe means securing a supplier whose engineering capabilities match your technical requirements. We proactively collaborate on material specifications, conduct joint failure mode analysis, and provide detailed mill test reports with every shipment. Our technical sales team, comprising metallurgists and process engineers, engages directly to resolve complex sourcing challenges. For your next requirement of precision 1 inch copper strip, initiate a technical consultation to experience our commitment to dimensional perfection and supply chain resilience. Contact Cathy Zhang, International Sales Manager, at cathy@transformerstrip.com to discuss your specific project parameters and receive a tailored capability statement.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 1 inch wide copper strip directly from China.