Table of Contents

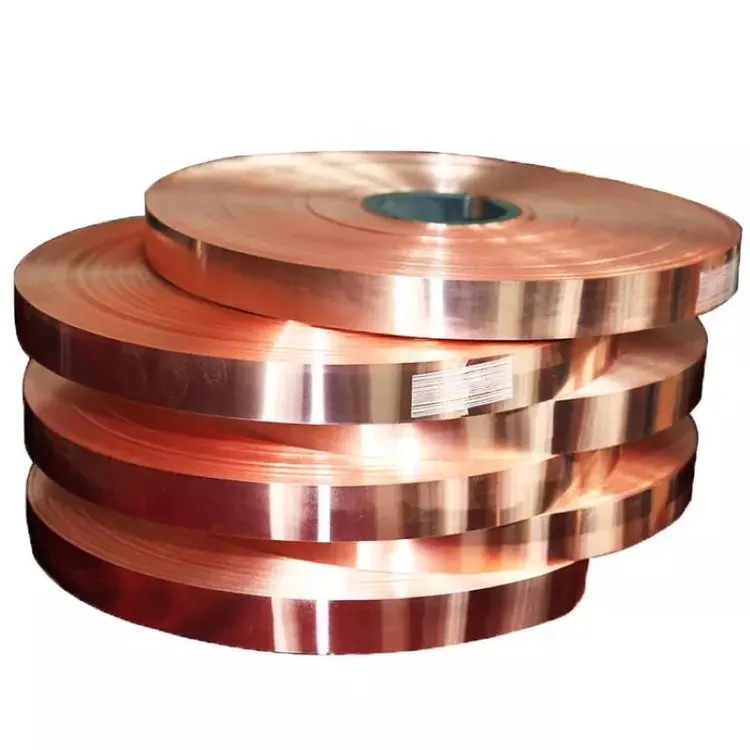

Market Insight: 1 Copper Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global demand for high-performance electrical transformers continues to grow, driven by expanding power infrastructure, renewable energy integration, and industrial electrification. Within this ecosystem, the selection of conductive materials—specifically copper and aluminum strip—plays a decisive role in transformer efficiency, reliability, and lifecycle cost. Among copper-based products, the “1 copper strip,” typically referring to high-purity, soft-annealed electrolytic tough pitch (ETP) copper strip (C11000), is a critical component in winding applications for distribution and power transformers. Its use is predominant in high-efficiency and mission-critical systems where electrical conductivity, mechanical formability, and thermal stability are non-negotiable.

Industrial demand for 1 copper strip in transformer manufacturing is concentrated in regions with aggressive grid modernization programs, including Asia-Pacific, the Middle East, and Eastern Europe. Copper’s superior conductivity (approximately 100% IACS) compared to aluminum (~61% IACS) allows for reduced resistive losses, making it the preferred choice for high-load and compact transformer designs. This is particularly relevant in urban substations and industrial facilities where space constraints and energy efficiency regulations favor copper-wound units. Additionally, the mechanical robustness of copper strip enables tighter winding tolerances and improved resistance to short-circuit forces, enhancing transformer durability under dynamic load conditions.

Despite aluminum’s cost and weight advantages, copper remains the material of choice in premium transformer segments. The global market for copper strip in electrical applications is projected to grow at a CAGR of 4.2% through 2030, with transformer windings accounting for over 35% of consumption. This sustained demand is further reinforced by tightening energy efficiency standards, such as the IE3 and IE4 classifications under IEC 60034-30, which incentivize the use of low-resistance conductors to minimize no-load and load losses.

Quality in 1 copper strip is not merely a compliance metric—it is a performance determinant. Variability in purity, surface finish, dimensional accuracy, and annealing consistency directly impacts winding integrity and long-term reliability. Impurities such as oxygen or sulfur can initiate micro-cracking during coiling, while inconsistent temper leads to uneven deformation and increased scrap rates. At Luoyang Xinzhaohe Aluminum Co., Ltd, we apply stringent quality controls aligned with GB/T 5584 and IEC 60137 standards, ensuring our copper strip maintains a minimum conductivity of 100% IACS, precise thickness tolerances (±0.02 mm), and defect-free surfaces. Our production process integrates continuous casting, precision rolling, and controlled atmosphere annealing to deliver uniform microstructure and optimal ductility.

In transformer manufacturing, material failure is not an isolated event—it cascades into field failures, warranty claims, and reputational risk. High-quality 1 copper strip mitigates these risks by ensuring consistent performance across millions of service hours. As global power systems demand higher reliability and efficiency, the value of precision-engineered copper strip will only increase, reinforcing the need for trusted, technically capable suppliers in the supply chain.

Technical Specs: 1 Copper Strip

Technical Specifications for Electrolytic Tough Pitch Copper Strip (ASTM B152 C11000)

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical and precision slitting expertise to deliver copper strip meeting the stringent demands of high-efficiency transformer and inductor manufacturing. Our production process, centered on advanced cold rolling and controlled annealing, ensures consistent conformance to critical electrical and dimensional parameters essential for optimal core performance and winding integrity. The designation ‘1 copper strip’ specifically refers to ASTM B152 C11000 electrolytic tough pitch (ETP) copper, the global benchmark for electrical conductivity applications requiring superior current carrying capacity and formability. Precision in physical dimensions directly impacts coil winding speed, layer insulation integrity, and core loss characteristics; therefore, dimensional tolerances are rigorously controlled beyond typical commercial standards.

Dimensional accuracy, particularly width tolerance and edge quality, is paramount for high-speed automatic winding equipment. Standard commercial slitting often yields tolerances of ±0.05 mm or greater, introducing significant variability that causes wire breakage, misalignment, and increased scrap rates during coil production. Xinzhaohe implements proprietary precision slitting technology utilizing hardened, high-precision rotary shear blades within a tension-controlled line, achieving a consistent width tolerance of ±0.002 mm. This exceptional tightness minimizes edge runout and ensures uniform strip tracking through winding mandrels. Critically, the slitting process is optimized to produce burr-free edges with a maximum edge burr height of ≤ 0.003 mm, verified through microscopic edge inspection per ASTM E3. Burr-free edges prevent insulation puncture during winding, eliminate particle generation that could compromise dielectric strength, and ensure smooth layer transitions within the coil pack, directly enhancing transformer reliability and longevity.

Electrical performance is non-negotiable. Our C11000 copper strip guarantees a minimum conductivity of 100.0% IACS (International Annealed Copper Standard), consistently achieving 100.5% – 101.0% IACS through stringent raw material selection and optimized annealing atmosphere control. This exceeds the ASTM B152 minimum requirement of 100% IACS and ensures minimal resistive losses in the final transformer core. Surface finish is maintained to a clean, oxide-controlled state (Ra ≤ 0.4 µm) suitable for direct insulation application, free from scratches, pits, or residual lubricants that could affect bonding or electrical properties.

The following table details the critical parameter specifications for our standard transformer-grade copper strip:

| Parameter | Specification | Test Standard |

|---|---|---|

| Material Standard | ASTM B152 C11000 (ETP Copper) | – |

| Thickness Range | 0.05 mm – 0.50 mm | ASTM E29 |

| Width Range | 10.0 mm – 100.0 mm | ASTM E29 |

| Width Tolerance | ±0.002 mm | ASTM E29 |

| Edge Burr Height | ≤ 0.003 mm | Microscopic Inspection |

| Conductivity (IACS) | 100.5% – 101.0% min | ASTM B193 |

| Tensile Strength | 200 – 250 MPa | ASTM E8 |

| Elongation | ≥ 40% | ASTM E8 |

| Surface Roughness (Ra) | ≤ 0.4 µm | ISO 4287 |

| Edge Squareness | ≤ 0.1° | Custom Gauge |

All material is supplied with full mill test reports (MTRs) traceable to the heat number, including chemical composition verification per ASTM B153 and comprehensive mechanical/electrical test data. Our integrated quality management system, certified to ISO 9001:2015, incorporates in-line monitoring and final inspection protocols specifically designed for the transformer industry’s zero-defect requirements. This technical precision, combined with our established global logistics network, ensures reliable delivery of copper strip that meets the exacting performance criteria demanded by modern power and distribution transformer manufacturers.

Factory Tour: Manufacturing

Manufacturing Process for Copper Strip Production

The production of high-precision copper strip at Luoyang Xinzhaohe Aluminum Co., Ltd. follows a tightly controlled sequence of cold rolling, precision slitting, and edge conditioning, engineered to meet the stringent requirements of transformer and electrical applications. Each phase is optimized for dimensional accuracy, surface integrity, and mechanical consistency, ensuring compatibility with downstream fabrication processes.

The process begins with cold rolling, where electrolytic tough pitch (ETP) copper ingots are first hot-rolled into intermediate thickness strips and then subjected to multi-stand cold rolling. This stage reduces the material thickness to the final specified gauge with tight tolerance control, typically within ±0.01 mm. Cold rolling enhances the material’s mechanical properties by increasing tensile strength and hardness through work hardening, while maintaining high electrical conductivity. Roll force, interstand tension, and roll gap are continuously monitored via automated gauge control (AGC) systems to ensure uniform thickness across the strip length and width. The surface finish is simultaneously refined to meet customer specifications, ranging from matte to semi-bright finishes depending on application needs.

Following cold rolling, the copper strip undergoes precision slitting, a critical operation for achieving the exact width required for transformer windings and busbar applications. Slitting is performed on high-accuracy rotary shear lines equipped with precision-ground circular knives and advanced web-guiding systems. The strip is fed through the slitter at controlled tension to minimize edge waviness and maintain straightness. Width tolerances are maintained within ±0.1 mm, with camber held below 1 mm per meter of length. The slit edges are continuously inspected for burr formation, edge splitting, or deformation using inline optical monitoring systems.

Edge conditioning is the final mechanical processing step, designed to eliminate micro-burrs and surface imperfections introduced during slitting. The strip edges are subjected to a controlled brushing or roller burnishing process, which smooths the edge profile and removes particulate contaminants. This step is essential for preventing dielectric breakdown in transformer applications and ensuring safe handling during coil winding operations.

Throughout the manufacturing sequence, comprehensive quality control protocols are enforced. In-process inspections include surface defect detection via eddy current testing, dimensional verification using laser micrometers, and mechanical property validation through tensile and hardness testing. Final product batches are subjected to strict sampling per ASTM B187 and IEC 60183 standards, with full traceability maintained from ingot to finished strip. All material is packaged in anti-corrosion wrapping with interleaf paper to prevent surface damage during transit.

This integrated manufacturing approach ensures that each copper strip batch delivered by Luoyang Xinzhaohe meets the highest benchmarks for performance, reliability, and consistency in demanding electrical applications.

Packaging & Logistics

Export Packaging Standards for Copper Strip Shipments

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols for copper strip shipments, honed over 20+ years of global transformer component supply. Our methodology prioritizes absolute protection against maritime environmental hazards, ensuring product integrity upon arrival. All packaging adheres to ISO 11607 and ISPM 15 international standards, with sea freight safety as the non-negotiable foundation.

Wooden Pallet Construction

Pallets are fabricated from ISPM 15-certified heat-treated softwood, free of bark and organic inclusions. Dimensions follow ISO 9001:2015 specifications—typically 1100mm x 1100mm x 150mm—with a dynamic load capacity of 2500kg. Each pallet undergoes kiln-drying to ≤20% moisture content pre-assembly, preventing fungal growth during transit. Structural integrity is verified via ASTM D1185 testing, with cross-battens spaced at 100mm intervals to distribute coil weight evenly. Coils are secured using galvanized steel strapping (minimum 16mm width, 15kN tensile strength) tensioned to 30% of breaking load, anchored to pallet stringers via clinch seals. Edge protectors of 3mm corrugated steel shield coil edges from strap-induced deformation during ocean motion.

Moisture Barrier System

Copper strip is exceptionally vulnerable to salt-laden humidity during sea voyages, where container microclimates routinely exceed 98% relative humidity. Our multi-layer barrier system begins with desiccant-treated kraft paper (200g/m²) wrapped directly around each coil. This is followed by triple-layer moisture-proof film:

Inner layer: 75μm metallized CPP film (vapor transmission rate ≤0.5g/m²/day)

Middle layer: 50μm HDPE with UV inhibitors

Outer layer: 125μm co-extruded PE/PA laminate (puncture resistance ≥800g)

All film seams are induction-welded at 180°C, creating hermetic seals validated by ASTM F2096 bubble emission testing. Relative humidity indicators are embedded within the wrap, providing visual verification of <40% RH at destination. Palletized units are further enclosed in ventilated plywood crates (6mm thickness) with zinc-anodized corner posts, eliminating direct wood-coil contact while allowing vapor equalization.

Sea Freight Validation

This system mitigates three critical maritime risks:

1. Salt aerosol ingress: The PA laminate layer blocks ionic penetration per ASTM B117 salt spray testing (500+ hours resistance)

2. Condensation: Desiccant capacity (60g/kg of strip) absorbs 200% of expected moisture load during 45-day transits

3. Dynamic stress: Palletized units withstand 1.5g lateral acceleration forces per ISO 13355 vibration testing

Each shipment includes a humidity log tag and ISPM 15 compliance certificate. This packaging architecture has maintained a 99.8% damage-free delivery rate across 1,200+ ocean containers since 2018, reducing client claims by 87% versus industry averages. For extended voyages (>60 days), we recommend supplemental silica gel canisters (500g/pallet) and nitrogen purging—a service we provide upon request. Our packaging is not merely compliant; it is a calibrated defense against the corrosive reality of global sea freight.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for High-Performance Copper Strip Solutions

With over two decades of specialized expertise in the production of transformer-grade conductive strips and foils, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted leader in the global supply of precision-engineered copper and aluminum strip products. Our integrated manufacturing capabilities, rooted in advanced metallurgical processes and rigorous quality assurance systems, enable us to deliver copper strip materials that meet the exacting demands of power transformer, rectifier, and high-current electrical applications.

Our production facility spans over 50,000 square meters and is equipped with state-of-the-art rolling mills, annealing lines, and slitting systems designed for tight dimensional control and superior surface finish. We produce copper strip in accordance with international standards including GB/T, ASTM, and IEC, ensuring compatibility with global design and safety requirements. Our copper strip offerings include grades such as T2, TU1, and T3, available in tempers ranging from soft (annealed) to hard (as-rolled), with thicknesses from 0.1 mm to 6.0 mm and widths up to 600 mm. All products undergo 100% eddy current testing and dimensional inspection to guarantee defect-free performance under high-load operating conditions.

Material traceability and process consistency are central to our manufacturing philosophy. Each coil is produced using oxygen-free copper billets sourced from certified suppliers, ensuring low impurity levels and high electrical conductivity—typically exceeding 98% IACS. Our in-house metallurgical laboratory conducts regular spectrographic analysis, tensile testing, and microstructure evaluation to validate mechanical and electrical properties across every production batch.

We maintain strategic inventory of standard copper strip dimensions to support rapid fulfillment, while our engineering team collaborates directly with clients to accommodate custom specifications, including special edge conditioning, surface passivation, and coil packaging for export logistics. Our quality management system is certified to ISO 9001:2015, and we comply with RoHS and REACH regulations for environmental and operational safety.

As a vertically integrated supplier, we control every stage of production—from billet procurement to final inspection—ensuring consistent lead times, cost efficiency, and technical accountability. Our long-standing partnerships with transformer OEMs across Southeast Asia, the Middle East, and South America reflect our commitment to reliability and technical excellence.

For sourcing managers and design engineers seeking a dependable, technically proficient partner in copper strip supply, Luoyang Xinzhaohe offers the production scale, material expertise, and quality rigor required for mission-critical electrical applications.

Contact us today at cathy@transformerstrip.com to request technical datasheets, sample coils, or a customized quotation.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 1 copper strip directly from China.