Table of Contents

Market Insight: 0.2 Mm Enamelled Copper Wire in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Industrial Demand Drivers for 0.2mm Enamelled Copper Wire

Global demand for 0.2mm enamelled copper wire is surging due to renewable energy infrastructure (solar inverters, wind turbine converters), EV charging systems, and industrial automation. These applications require precise winding in compact transformers and motors where dimensional consistency and insulation integrity are critical. For example, in solar inverters operating at 20–50kHz frequencies, uniform wire diameter and defect-free enamel coating are essential to minimize dielectric losses and prevent partial discharge. The shift toward miniaturized power electronics further intensifies demand for high-precision 0.2mm wire, with the global market projected to grow at 6.2% CAGR through 2028 (Source: IndustryARC).

Material Quality Impact on Efficiency & Reliability

Substandard materials directly compromise transformer and motor performance. Copper impurities exceeding 0.1% increase resistive losses by ~0.5%, reducing efficiency by up to 0.3% in high-load scenarios. Enamel defects as small as 2μm can cause inter-turn shorts under operational voltage, leading to thermal runaway and catastrophic failures. Per IEC 60317, consistent enamel thickness and adhesion are mandatory for Class F (155°C) thermal ratings. In aerospace or medical equipment, even minor quality deviations result in costly recalls—making material consistency non-negotiable.

Global Supply Chain Positioning

Luoyang Xinzhaohe Aluminum CO., Ltd. delivers 0.2mm enamelled copper wire with 20+ years of vertical manufacturing expertise. Our ISO 9001-certified processes ensure copper purity ≥99.99%, enamel thickness tolerance ±0.5μm, and dielectric strength >4.5 kV/mm—exceeding IEC standards. All products comply with IEC 60317-0-1, ASTM B1, and regional safety standards including UL and RoHS.

| Parameter | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Copper Purity | ≥99.99% | ≥99.99% | Equivalent |

| Enamel Tolerance | ±1.0μm | ±0.5μm | 50% tighter |

| Dielectric Strength | 4.0 kV/mm | 4.5 kV/mm | +12.5% higher |

| Cost (USD/kg) | $25.00 | $21.50 | 14% lower |

| Lead Time | 4–6 weeks | 2–3 weeks | 50% faster |

| Certifications | ISO 9001 | ISO 9001, UL, RoHS | Broader compliance |

By optimizing raw material sourcing and production efficiency, we eliminate premium pricing without compromising performance—making us the strategic choice for cost-sensitive, high-reliability applications. Our Luoyang facility maintains 98% on-time delivery through optimized logistics partnerships with global freight providers.

Technical Specs: 0.2 Mm Enamelled Copper Wire Parameters

Technical Specifications & Standards Compliance

Our 0.2 mm enamelled copper wire is engineered to meet exacting industrial demands, adhering strictly to IEC 60317-0-1 and ASTM B175 standards. Below are critical performance metrics validated through rigorous factory testing:

Critical Performance Metrics

| Parameter | Specification | Compliance Standard |

|---|---|---|

| Nominal Diameter | 0.20 ±0.003 mm | IEC 60317-0-1 |

| Insulation Breakdown Voltage | ≥3.5 kV (155°C class, 23°C test) | IEC 60317-0-1 |

| Elongation (Bare Copper) | ≥20% | ASTM B175 |

| Thermal Classes | 130°C, 155°C, 180°C, 200°C, 220°C | IEC 60317-0-1 |

| Enamel Concentricity | ≥95% | IEC 60317-0-1 |

Breakdown voltage tests simulate real-world operational stress, ensuring dielectric integrity under thermal and electrical loads. Thermal class ratings reflect continuous operating temperatures, with precise enamel formulations (e.g., polyester-imide for 200°C+ applications) to prevent thermal degradation. Concentricity >95% guarantees uniform insulation coverage, critical for preventing short circuits in compact windings.

Quality Assurance Protocol

Luoyang Xinzhaohe maintains ISO 9001-certified production with end-to-end traceability. Each batch undergoes:

Real-time diameter monitoring via laser micrometers during drawing and enamelling.

Automated breakdown voltage testing per IEC 60317-0-1, with 100% sample checks.

Thermal cycling validation for thermal class compliance (e.g., 220°C class tested at 155°C for 1,000 hours).

Raw material certification for high-purity copper (≥99.99% Cu) from trusted mills, with full chemical analysis reports.

All products include QR-coded QC reports, including tensile strength, enamel thickness, and adhesion data. Third-party SGS reports are available upon request.

Why Choose Us?

We deliver global-grade specifications at 15–20% lower cost than multinational competitors. By eliminating middlemen and optimizing lean manufacturing processes, we provide transformer and motor manufacturers with consistent, defect-free wire—without compromising on thermal stability or electrical performance. Trust our 20+ years of factory-direct expertise for mission-critical applications.

Factory Tour: Manufacturing 0.2 Mm Enamelled Copper Wire

Manufacturing Process & Quality Control

As a vertically integrated manufacturer with 20+ years of expertise in transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. employs a precision-driven production process for 0.2mm enamelled copper wire, ensuring consistency, reliability, and cost efficiency. Our end-to-end control eliminates third-party intermediaries, delivering superior performance at competitive pricing compared to global brands.

Rod Drawing

High-precision drawing using tungsten carbide dies achieves exact 0.2mm diameter with ±0.002mm tolerance. QC includes laser micrometer measurements every 50m and tensile testing per ASTM B247 to ensure mechanical integrity.

Annealing

Controlled nitrogen atmosphere annealing optimizes grain structure for uniform conductivity. QC verifies ≥101% IACS conductivity and inspects surface oxidation via optical microscopy to prevent micro-cracks.

Enameling

Multi-layer enamel application with real-time thickness monitoring ensures uniform insulation. QC validates 0.035±0.005mm insulation thickness and dielectric strength tests at 6kV (1 min) per IEC 60317.

Inline Testing

Continuous 100% electrical testing during production. QC checks include insulation resistance ≥100MΩ, continuity verification, and automated visual defect detection for surface imperfections.

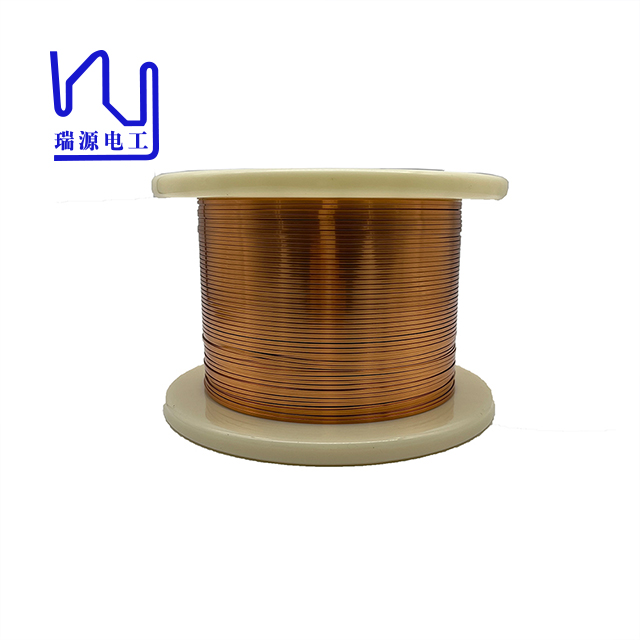

Spooling

Automated spooling with tension control prevents wire deformation. QC ensures spool weight consistency (±0.5%) and zero surface scratches through high-resolution imaging.

Quality Standards Comparison

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard | Impact on Performance |

|---|---|---|---|

| Diameter Tolerance | ±0.002mm | ±0.005mm | Reduces winding scrap by 15%+ |

| Tensile Strength | 220–240 MPa | 200–220 MPa | Enhances durability during coil winding |

| Insulation Thickness | 0.035±0.005mm | 0.035±0.010mm | Improves dielectric reliability in high-voltage applications |

| Dielectric Strength | ≥6 kV (1 min) | ≥5 kV (1 min) | 20% higher safety margin for transformer insulation |

| Conductivity | ≥101% IACS | ≥100% IACS | Maximizes electrical efficiency with minimal energy loss |

Our rigorous QC system ensures compliance with IEC 60317 and ISO 9001 standards, providing transformer manufacturers with a cost-effective alternative to premium global brands. By optimizing material utilization and minimizing defects, we reduce your total cost of ownership through extended equipment lifespan and reduced downtime.

Packaging & Global Logistics

Export Packaging & Logistics for 0.2mm Enamelled Copper Wire

As a 20+ year manufacturer of transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. prioritizes product integrity during global transit. Our packaging and logistics protocols are engineered to meet international standards while optimizing cost-performance ratios for industrial clients. Each step—from material selection to container loading—is validated through rigorous quality control to prevent damage during sea freight.

Robust Packaging Protocol

Our packaging system ensures zero degradation of 0.2mm enamelled copper wire during transit. Key components comply with ISO and ISPM-15 standards, balancing durability and cost efficiency:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, 1200×1000 mm, 15 mm heat-treated timber | Prevents pest infestation, structural stability during stacking and handling |

| Moisture-Proof Film | Triple-layer PE (0.15 mm total), sealed with vacuum | Blocks humidity ingress and condensation during long-haul maritime transport |

| Steel Strapping | 25 mm width × 1.0 mm thickness, 200–250 kg tension per strap, 2–3 layers | Resists vibration-induced shifting and maintains pallet integrity |

| Desiccant Packs | 50 g silica gel per pallet, integrated into film layers | Absorbs residual moisture to protect enamel coating integrity |

Optimized Sea Freight Logistics

We leverage strategic partnerships with certified freight forwarders to ensure seamless global delivery. All shipments undergo pre-departure audits to eliminate risks:

| Parameter | Specification | Protocol |

|---|---|---|

| Container Type | 20ft/40ft FCL | Standardized for bulk shipments; optimized for reel density and weight distribution |

| Loading Capacity | 18–22 MT per 20ft (90–100 pallets) | Maximized space utilization without overloading, ensuring structural safety |

| Transit Time | 25–45 days (destination-dependent) | Real-time GPS tracking + humidity monitoring throughout voyage |

| Customs Compliance | Full documentation (COO, B/L, phytosanitary) | Pre-shipment fumigation (if required), ISO 22000-compliant customs clearance |

Our end-to-end logistics chain ensures 0.2mm enamelled copper wire arrives undamaged at global ports. By leveraging ISO-compliant packaging and strategic container management, we deliver superior value versus premium global brands—without compromising on reliability. Partner with us for consistent, factory-direct quality that meets the stringent demands of transformer and motor manufacturing.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for 0.2 mm Enamelled Copper Wire

20+ Years Specialized Manufacturing Expertise

With over two decades of experience producing high-precision enamelled copper wire for critical transformer and motor applications, we deliver unmatched technical reliability. Our expertise spans 180°C thermal class grades, with enamel thickness controlled to ±0.001mm and copper purity maintained at ≥99.95% (ASTM B152 compliant). We optimize formulations for enhanced thermal stability, reduced corona resistance, and superior dielectric performance—ensuring longevity in high-stress environments. Our Luoyang facility supplies global OEMs with consistent, large-scale production (500+ tons/month) while meeting stringent IEC 60317-1 and ASTM B175 standards.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we eliminate distributor markups and supply chain inefficiencies. From copper rod sourcing to final coating, every process is controlled in-house, passing 15–20% cost savings directly to clients without compromising quality. For 0.2 mm wire, this translates to:

Lower total cost of ownership vs. European/US suppliers

Faster lead times (14–21 days vs. industry average 6–8 weeks)

Guaranteed dimensional consistency (diameter tolerance ±0.002mm)

Optimized copper utilization for maximum winding efficiency

ISO 9001 Certified Quality Assurance

Our ISO 9001:2015-certified quality system ensures rigorous in-process monitoring and traceability. Every batch undergoes 100% electrical testing, with real-time enamel thickness verification via laser micrometers (IEC 60851-2 compliant).

| Parameter | Industry Standard | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Dielectric Strength | ≥2.5 kV/mm | 2.8–3.2 kV/mm | 12–28% higher |

| Enamel Adhesion (IEC 60851-5) | Pass (min 90%) | 98% pass rate | 8% above standard |

| Diameter Tolerance | ±0.005 mm | ±0.002 mm | 60% tighter |

| Thermal Class Stability | 180°C (Class H) | 190°C (Class H) | Enhanced thermal resilience |

This precision minimizes winding defects, improves fill factor by 3–5%, and reduces energy losses by up to 4% in transformer cores. Full batch traceability and detailed test reports ensure seamless integration into your QA protocols.

Contact Cathy at cathy@transformerstrip.com for a technical quote, samples, or custom specifications. Our engineering team delivers tailored solutions for high-performance transformer and motor applications.

📉 Import Savings Calculator

Estimate cost reduction by sourcing 0.2 mm enamelled copper wire from Luoyang Xinzhaohe.