Table of Contents

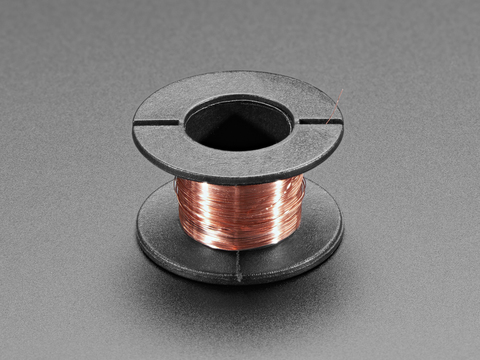

Market Insight: 0.1 Mm Enamelled Copper Wire

Market Analysis: Industrial Demand for 0.1 mm Enamelled Copper Wire in Transformers

The global demand for 0.1 mm enamelled copper wire is driven by relentless miniaturization and efficiency requirements across high-frequency power electronics. This ultra-fine gauge wire is critical in advanced transformer applications where space constraints and thermal management are paramount, particularly within switch-mode power supplies (SMPS), high-frequency inductors, and compact isolation transformers. Key growth sectors include electric vehicle (EV) onboard chargers, 5G infrastructure power modules, medical imaging equipment, and ultra-slim consumer electronics adapters. These applications operate at frequencies exceeding 100 kHz, necessitating reduced core sizes and lower eddy current losses, which directly translates to the adoption of finer wire gauges. The 0.1 mm diameter represents a significant engineering threshold; below this point, handling complexity increases exponentially while maintaining required electrical performance. Market expansion is further accelerated by stringent global energy efficiency regulations (e.g., EU CoC Tier 2, DOE Level VI), which compel manufacturers to optimize magnetic component design, often selecting 0.1 mm wire to achieve higher turns density without compromising thermal dissipation.

Quality integrity in 0.1 mm enamelled copper wire is non-negotiable due to the extreme operational stresses inherent in these applications. At this micron-scale diameter, microscopic defects in the enamel insulation become critical failure points. A single pinhole or thin spot in the polyurethane, polyester-imide, or advanced nanocomposite coating—imperceptible to the naked eye—can initiate partial discharge under high dv/dt switching conditions common in modern power electronics. This rapidly propagates into insulation breakdown, causing catastrophic short circuits within densely wound coils. Furthermore, the high current density associated with fine wire exacerbates thermal stress; inadequate thermal class rating (e.g., Class 200 vs. required Class 220) leads to accelerated enamel degradation and reduced transformer lifespan. Mechanical properties are equally vital; insufficient elongation or tensile strength results in wire breakage during high-speed automated winding processes, causing production line stoppages and scrap rates exceeding 15% in demanding applications. Consistent dimensional tolerances (±0.003 mm) are essential to prevent inter-turn shorts and ensure predictable fill factors in precision-wound bobbins.

The consequences of substandard 0.1 mm wire extend beyond immediate manufacturing yield loss. Field failures in mission-critical systems—such as EV charging infrastructure or medical devices—trigger costly recalls, warranty liabilities, and reputational damage. Performance inconsistencies directly impact end-product efficiency; variations in conductor resistivity or enamel dielectric properties increase I²R losses and electromagnetic interference (EMI), potentially causing non-compliance with EMC directives. Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical process control and supply chain expertise to mitigate these risks. Our rigorous quality protocols include 100%在线火花测试 (in-line spark testing at 1500 VDC), automated optical diameter monitoring, and accelerated thermal aging validation per IEC 60317 standards. Sourcing partners must demonstrate capability in statistical process control for ultra-fine wire drawing and precision enameling—factors that ultimately determine transformer reliability, power density, and total cost of ownership in high-value electronics markets. Compromising on wire quality at 0.1 mm gauge inevitably escalates lifecycle costs despite marginal initial savings.

Technical Specs: 0.1 Mm Enamelled Copper Wire

Technical Specifications for 0.1 mm Enamelled Copper Wire

Luoyang Xinzhaoang Aluminum Co., Ltd., with over two decades of specialized manufacturing expertise in winding wire technologies, provides this technical reference for 0.1 mm diameter enamelled copper wire. This fine gauge wire is engineered for high-performance electromagnetic applications requiring precision winding, thermal resilience, and dielectric reliability. The following specifications reflect industry-compliant performance metrics aligned with IEC 60317 and GB/T 6109 standards, ensuring compatibility with motors, transformers, sensors, and micro-coil assemblies.

The conductor material is high-purity electrolytic tough pitch (ETP) copper, drawn to a nominal diameter of 0.100 mm with a tolerance of ±0.003 mm. The wire is coated with a thermosetting polymer insulation system designed to deliver consistent electrical isolation, mechanical durability, and thermal endurance. The insulation is applied via precision multi-layer coating technology to ensure uniform thickness and defect-free coverage, critical for reliability in high-density winding configurations.

Dielectric strength, or insulation breakdown voltage, is a critical parameter for ensuring operational safety and long-term reliability. For the 0.1 mm enamelled copper wire, the minimum insulation breakdown voltage is measured at 1,800 V AC (rms) under standard test conditions (room temperature, 50 Hz, immersed in water). This value exceeds the baseline requirements for Class B (130°C) and supports higher thermal classes, minimizing the risk of short circuits in compact electromagnetic devices.

Elongation is a key mechanical property that reflects the wire’s ductility and resistance to fracture during winding and coil processing. The typical elongation at break for this product is not less than 12%, as measured on a 25 mm gauge length. This ensures compatibility with high-speed automatic winding equipment and reduces the incidence of wire breakage during production, enhancing yield and process efficiency.

Thermal performance is defined by the thermal class rating, which indicates the maximum continuous operating temperature the insulation can withstand without significant degradation. The 0.1 mm enamelled copper wire is available in multiple thermal classes, ranging from 130°C (Class B) up to 220°C (Class H+). Each class corresponds to a specific polymer system—such as polyesterimide, polyamide-imide, or modified polyurethane—optimized for thermal stability, chemical resistance, and mechanical adhesion. Higher thermal classes are recommended for applications exposed to elevated ambient temperatures or frequent thermal cycling.

The following table summarizes the core technical parameters:

| Parameter | Value / Range | Test Standard |

|---|---|---|

| Nominal Conductor Diameter | 0.100 mm | IEC 60317 |

| Diameter Tolerance | ±0.003 mm | IEC 60317 |

| Insulation Breakdown Voltage | ≥1,800 V AC (rms) | IEC 60317-1 |

| Elongation at Break | ≥12% | IEC 60317-1 |

| Thermal Class Options | 130°C (B), 155°C (F), 180°C (H), 200°C, 220°C | IEC 60317 |

| Insulation Material | Polyesterimide, Polyamide-imide, Modified Polyurethane | GB/T 6109 |

| Recommended Applications | Micro-motors, Sensors, Transformers, Relays | — |

These specifications are subject to batch certification and can be customized based on client requirements for adhesion, thermal shock resistance, or solvent resistance. Luoyang Xinzhaohe Aluminum Co., Ltd. maintains strict quality control through in-line monitoring and third-party verification to ensure consistency across production runs.

Factory Tour: Manufacturing

Manufacturing Process for 0.1 mm Enamelled Copper Wire

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized expertise in winding wire production to manufacture ultra-fine 0.1 mm enamelled copper wire. This precision process demands rigorous control at every stage to achieve the required mechanical integrity, electrical performance, and insulation reliability essential for demanding applications like micro-motors and precision electronics. The production sequence begins with high-conductivity electrolytic tough pitch (ETP) copper rod, typically 8 mm diameter, conforming to IEC 600228 Class 1 standards. The rod undergoes multi-pass drawing through precision tungsten carbide or diamond dies within a continuous rod drawing machine. For 0.1 mm gauge, this involves numerous reductions under precisely controlled tension and lubrication, typically using aqueous emulsions, to minimize work hardening and surface defects. Diameter is continuously monitored via non-contact laser micrometers, ensuring strict adherence to the ±0.004 mm tolerance envelope specified for this ultra-fine gauge.

Immediately following the final draw pass, the wire enters an inline continuous annealing furnace. This critical step restores ductility lost during drawing. The wire traverses a precisely controlled inert atmosphere furnace zone, typically using nitrogen or nitrogen-hydrogen mixtures, heated to 450-550°C. Residence time and temperature profile are meticulously calibrated to achieve optimal recrystallization without grain growth that could compromise tensile strength or elongation. Post-annealing, the wire is rapidly quenched using deionized water sprays to lock in the desired soft temper, achieving a tensile strength of 150-220 MPa and elongation exceeding 15%, as verified by inline tensile testers.

The annealed conductor then proceeds to the enameling station. Multiple fine layers of thermosetting polymer resin are applied via precision capillary or die coating systems. For 0.1 mm wire, achieving a uniform, pinhole-free enamel film with a total build thickness of 0.015-0.025 mm is paramount. Common insulation systems include single or dual-layer constructions utilizing polyurethane, polyesterimide, or polyamide-imide resins, selected based on the required thermal class (e.g., 155°C, 180°C, 200°C). Each applied layer is immediately cured in high-temperature ovens (350-450°C) under controlled atmosphere to drive solvent evaporation and complete polymer cross-linking. The selection of enamel type directly impacts key performance characteristics:

| Enamel Type | Typical Thermal Class | Key Advantages for 0.1 mm Wire |

|---|---|---|

| Polyurethane | 130°C – 155°C | Excellent solderability, good abrasion resistance |

| Polyesterimide | 180°C | Superior thermal stability, chemical resistance |

| Polyamide-imide | 200°C – 220°C | Exceptional thermal endurance, mechanical toughness |

Comprehensive inline quality control is integral throughout the process. Critical checks include continuous diameter monitoring (laser micrometer), enamel thickness verification (capacitance or optical methods), high-potential (hi-pot) testing at minimum 1000 V DC to detect insulation flaws, and continuous monitoring of winding tension and surface quality via optical inspection systems. Final quality assurance involves rigorous batch testing per IEC 60317 standards, encompassing conductor resistance, elongation, springiness, thermal shock, scrape abrasion resistance, and dielectric breakdown voltage. This systematic approach ensures every spool of 0.1 mm enamelled copper wire meets the stringent dimensional, electrical, and mechanical specifications demanded by advanced electromechanical components.

Packaging & Logistics

Export Packaging for 0.1 mm Enamelled Copper Wire – Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in precision winding wires, we recognize that effective export packaging is not merely a logistical consideration but a critical component in preserving the electrical and mechanical integrity of fine gauge enamelled copper wire, particularly at 0.1 mm diameter. This dimension demands exceptional care due to its susceptibility to mechanical deformation, oxidation, and moisture absorption, all of which can compromise performance in end-use applications such as micro-motors, transformers, and high-frequency inductors.

For international shipments, our standard export packaging system is engineered to meet the rigorous demands of sea freight, which presents prolonged exposure to humidity, temperature fluctuations, and dynamic mechanical stresses. All coils of 0.1 mm enamelled copper wire are first wound under controlled tension and inspected for surface defects prior to packaging. Each coil is then individually wrapped in multi-layer moisture-proof composite film, which acts as a vapor barrier with a water vapor transmission rate (WVTR) of less than 0.5 g/m²·24h at 38°C and 90% RH. This film incorporates aluminum foil lamination to ensure maximum resistance against ambient moisture and corrosive marine atmospheres.

The sealed coils are subsequently arranged on high-grade, ISPM-15 compliant wooden pallets. These pallets are constructed from heat-treated hardwood, providing structural rigidity and load distribution essential for containerized shipping. The use of wooden pallets also allows for secure strapping and load stabilization, minimizing coil movement during transit. Each pallet is designed to support stacking loads of up to 4,000 kg without deformation, ensuring stability in multi-tier container storage.

After placement on the pallet, the entire load is stretch-wrapped with UV-resistant polyethylene film and further encased in a sealed polyethylene hood. This dual-layer protection prevents condensation ingress during temperature cycling, a common occurrence in intercontinental sea transport. A desiccant pack is placed within the outer hood to absorb any residual moisture, maintaining an internal relative humidity below 40% throughout the shipment duration.

All packages are clearly labeled with handling instructions, including “Keep Dry,” “Do Not Stack Heavily,” and “Fragile – Precision Winding Wire,” alongside barcoded lot identifiers for full traceability. This packaging protocol has been validated through accelerated climatic testing simulating 60-day ocean voyages and has consistently demonstrated zero degradation in enamel adhesion, dielectric strength, or conductor resistivity.

By integrating moisture-proof materials, structurally robust palletization, and climate-responsive design, Luoyang Xinzhaohe ensures that every shipment of 0.1 mm enamelled copper wire arrives at its destination with uncompromised quality, ready for high-precision industrial processing.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision 0.1 mm Enamelled Copper Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical and winding wire manufacturing expertise to deliver exceptional 0.1 mm enamelled copper wire, meeting the stringent demands of high-performance electromagnetic components. Our core strength lies in mastering the precise production of micro-diameter conductors, where dimensional stability and enamel integrity are paramount. We utilize advanced continuous annealing systems with tightly controlled inert atmospheres, ensuring optimal electrical conductivity (exceeding 100% IACS) and superior mechanical properties in the base copper. The drawing process employs diamond dies with micron-level calibration and real-time tension monitoring, consistently achieving the critical 0.100 ± 0.002 mm outer diameter tolerance required for dense, reliable coil winding in miniature transformers, sensors, and high-frequency inductors.

Our enamelling technology is engineered for ultra-thin, defect-free coatings on this challenging gauge. We deploy multi-zone vertical ovens with precise temperature profiling and solvent management systems, enabling the application of advanced thermosetting polymer resins—including polyesterimide (PEI) and polyamide-imide (PAI)—to exact thickness specifications. This process guarantees exceptional thermal class performance (up to 180°C, Class H), outstanding dielectric strength (minimum 3000 Vrms for 0.1 mm wire), and critical thermal shock resistance down to -65°C, essential for automotive and aerospace applications. Rigorous in-line monitoring of enamel build, surface smoothness, and continuity, coupled with 100% spark testing at elevated voltages, ensures every meter of wire meets IEC 60317 and customer-specific performance criteria before shipment.

Vertical integration within our dedicated winding wire facility provides significant supply chain advantages. We maintain strict control over copper rod sourcing, drawing, annealing, and enamelling processes under one roof, minimizing variability and enhancing traceability from raw material to finished product. This integrated approach, combined with ISO 9001 and IATF 16949 certified quality management systems, delivers unparalleled batch-to-batch consistency. Our production planning utilizes real-time data analytics to optimize throughput for micro-wire orders, while strategic raw material inventory buffers ensure resilience against market fluctuations. Global logistics are streamlined through established partnerships with freight forwarders specializing in temperature-controlled and ESD-sensitive shipments, guaranteeing on-time delivery to OEMs and tier suppliers worldwide with minimal lead time variance.

Partnering with Luoyang Xinzhaohe mitigates technical and supply chain risks inherent in sourcing critical 0.1 mm enamelled wire. We provide comprehensive technical documentation, including full material test reports (MTRs), UL recognition files (where applicable), and metallurgical process validation data. Our engineering team collaborates directly with your R&D and procurement departments to resolve application-specific challenges and support new product introductions. For guaranteed supply of high-reliability 0.1 mm enamelled copper wire backed by 20 years of precision manufacturing discipline, contact our Technical Sales Manager Cathy directly. Initiate a technical review or request a sample qualification package to validate our capability for your demanding applications.

Contact Cathy at cathy@transformerstrip.com to discuss your specific 0.1 mm enamelled copper wire requirements and secure a resilient, high-performance supply partnership.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 0.1 mm enamelled copper wire directly from China.